Coil Anodizing

Achieve durability, corrosion-resistance, and beauty with Lorin aluminum anodizing

Lorin Industries specializes in aluminum anodizing to improve the aesthetics and wear protection for a variety of aluminum.

Lorin Coil Anodizing offers an advanced electro-chemical process that creates an anodic film to safeguard aluminum. This process shields the base metal from corrosion, wear, and environmental damage, while also providing a customizable decorative finish.

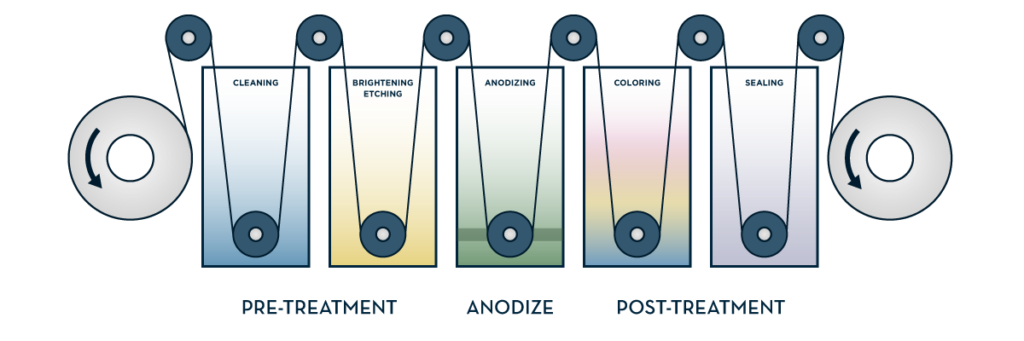

COIL ANODIZING PROCESS

From pre-treatment to anodizing to post-treatment, each phase of the Coil Anodizing Process protects the aluminum and offers a vast range of vibrant colors, hues and finishes that provide an esthetically pleasings and durable finish.

Cleaning: An Essential Step in Anodizing Pre-Treatment for Raw Aluminum Preparation

Cleaning removes any contaminants from the surface of the aluminum, such as dirt, grease, oils, oxides, or other foreign materials. By removing these contaminants the quality of the anodized finish is improved.

Brightening & Etching: An Essential Process for Smoothing and Eliminating Imperfections

The brightening and etching processes are integral to anodizing pre-treatment as they play a vital role in effectively smoothing surface roughness, eliminating imperfections, and controlling the final finish of the aluminum surface.

Anodizing: Creating an Anodic Film Using Aluminum as a Base

After pre-treatment, an anodic film is built from the aluminum itself. An electrical current is passed through an electrolyte bath in which the aluminum has been immersed. The anodic thickness can be tightly controlled and is hard and porous for accepting coloring dyes.

Coloring: Enhancing Aluminum with Endless Possibilities of Colors & Hues

Anodizing coloring is a process that adds color to anodized aluminum. Methods like absorptive dye coloring and electrolytic coloring offer a vast range of vibrant hues, providing endless possibilities.

Sealing: Preserving Colors and Enhancing Durability of Anodized Aluminum

Sealing is the process of closing the pores in the anodic film, effectively locking in the colors and creating a surface that is highly resistant to staining, abrasion, and color degradation. This sealing step enhances the durability and longevity of the anodized aluminum, ensuring that the colors remain vibrant and intact over time. It also provides additional protection against external factors such as moisture, chemicals, and UV radiation, further enhancing the overall performance and appearance of the anodized aluminum.

Understanding Coil vs Batch Anodizing

For a more in-depth understanding of the differences between coil vs. batch anodizing, we invite you to watch our informative video that explores the nuances of these two anodizing processes.

Anodizing Aluminum Process

To gain a comprehensive understanding of the aluminum anodizing process, we invite you to watch our video showcasing the step-by-step transformation of aluminum through coil anodization.

Lorin Anodized Aluminum: Redefining Elegance with Captivating Brilliance

Explore the allure of Lorin Anodized Aluminum as it redefines elegance with captivating brilliance, unveiling a mesmerizing dance of light, enchanting shadows, and reflections that effortlessly embody refined beauty.

Request Information

Send us a question and one of our team members will be in touch.

"*" indicates required fields