Debunking myths surrounding crazing

Muskegon, MI – Lorin Industries, Inc., the industry leader in the innovation and production of coil anodized aluminum, dispels some myths about forming anodized aluminum that include how it could compromise the integrity of the metal, become a source point for corrosion, and lack visual appeal.

What is crazing? Crazing occurs when bending or forming any metal because nothing is infinitely flexible. Micro-fractures of the surface will occur as the top part of the bend stretches the metal around the bend. This micro-fracturing, or stretching of the metal does not compromise the structural integrity of the metal. Cracking is different from crazing. Cracking occurs when the metal is bent beyond its mechanical property limits and cracks. This cracking does compromise the structural integrity of the metal. So to confirm, cracking of the metal compromises the structural integrity of the metal, crazing does not.

Misbeliefs that crazing compromises performance in anodized aluminum or that anodized aluminum is just as susceptible to corrosion as coated products can now be put to rest with an understanding of the anodizing process. Lorin’s anodizing process builds a protective anodic layer through an electrochemical process that converts the aluminum into aluminum oxide. This makes the anodic layer part of the aluminum as it is bonded at the molecular level. Because this layer is not a coating, any bend and subsequent crazing micro-fractures will not be a source point from which corrosion can precipitate. While a coating that is bent can result in chipping, flaking, and peeling, anodized aluminum will never chip, flake or peel.

For some materials the crazing may be more visible than others. Even if not visible, light reflecting off of the bend point will also always create a frosted looking effect. So from a visual standpoint, the frosted effect will be there, there’s just no getting around it. With the anodic layer of anodized aluminum being the same chemical composition and 3-dimensional crystalline structure as a Sapphire, it will reflect and refract the light even more, adding an element of brilliance and distinction without compromising the performance.

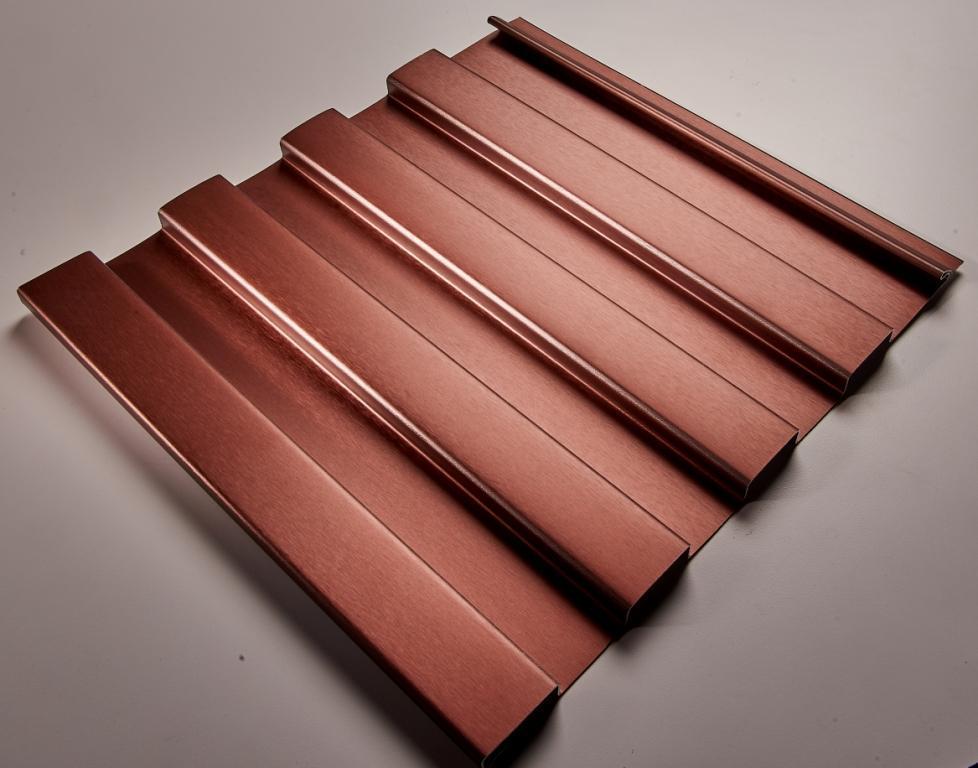

This visual effect is widely accepted and embraced in many applications and industries. Even when not looking at the bend point, each angle of view offers a unique perspective, making the surface come alive with color and light. This is unique to anodized products and cannot be achieved with paint or a coating process.

First image: ATAS standing seam panel

Second image: PAC-CLAD standing seam panel

In summary, crazing does not degrade the performance of anodized aluminum, it just shows off how anodizing enhances the aluminum. It is proof that the aluminum is protected. It also adds to the visual appeal of anodized aluminum, resulting in a unique look that will not chip, flake, or peel unlike other coated or painted products.

###

About Lorin

Lorin Industries, Inc. has provided coil anodized aluminum to global markets for over 70 years. Starting with architectural markets in 1953, our excellence continues today with industry-leading innovation and manufacturing. Lorin’s coil anodized aluminum products have been used for automotive, transportation, consumer appliances, and other industries, and we have worked with some of the world's foremost architects, designers, and fabricators to create new and exciting building designs that last throughout generations. The possibilities are infinite. At Lorin, we can help you reflect your vision with coil anodized aluminum.